LOGIBOX

- more than packaging

LOGIBOX is a profitable investment

ENHANCED MATERIAL HANDLING

The use of Logibox enabled outdoor storage of products. The time used to process the material was decreased by one man-year, and hall space was significantly freed up

NO DISPOSABLE PACKAGINGS

The transfer of products to assembly in another location can be done without single-use packaging. Logiboxes move between locations

NO RECYCLING FEES FOR PACKAGING

Sales and facts

LOGIBOX – packaging

LOGIBOX is a unique packaging solution, by using Logibox you will get significant savings in transport and storage costs of light products. In particular, its advantages are highlighted when products are regularly delivered between two locations.

The investment in Logiboxes typically pays for itself in less than a year.

As an example, the recycling-logistics of used fluorescent lamps, where used fluorescent lamps are collected in Logibox packages and when full, they are delivered to the processing unit. Empty boxes are returned to the starting point. Cost efficiency improvement is more than 50%.

LOGIBOX – packaging for efficient logistics

When fully packed, three Logiboxes can be stacked on top of each other and thus the transport space is utilized to the maximum, or the storage of light products can be done without storage shelves and even, if necessary, outdoors.

When empty, Logiboxes can be stored or delivered stacked with 10 to 12 pieces inside each other and the lids on top. This significantly saves transport and storage space.

LOGIBOX – increasing profitability through savings

By using Logibox, savings start to accumulate from the first day of use. Improved transportation, storage and packaging handling bring significant cost savings year after year.

Savings also occur when you no longer need cardboard packaging and separate pallets. Packaging waste is no longer generated as it used to be, and savings also come from recycling fees.

Return freight for empty boxes is very cost-effective. Example; A 13-meter trailer fits 42 full Logibox packages. When they are returned to the starting point, they only take up 1/3 of the transport space of full boxes (42 empty boxes takes up only 3.6 LDM!)

For example, companies recycling used fluorescent lamps have saved up to more than 50% in freight and logistics costs. The payback period of the investment has typically been well under a year.

LOGIBOX – durable and ecological

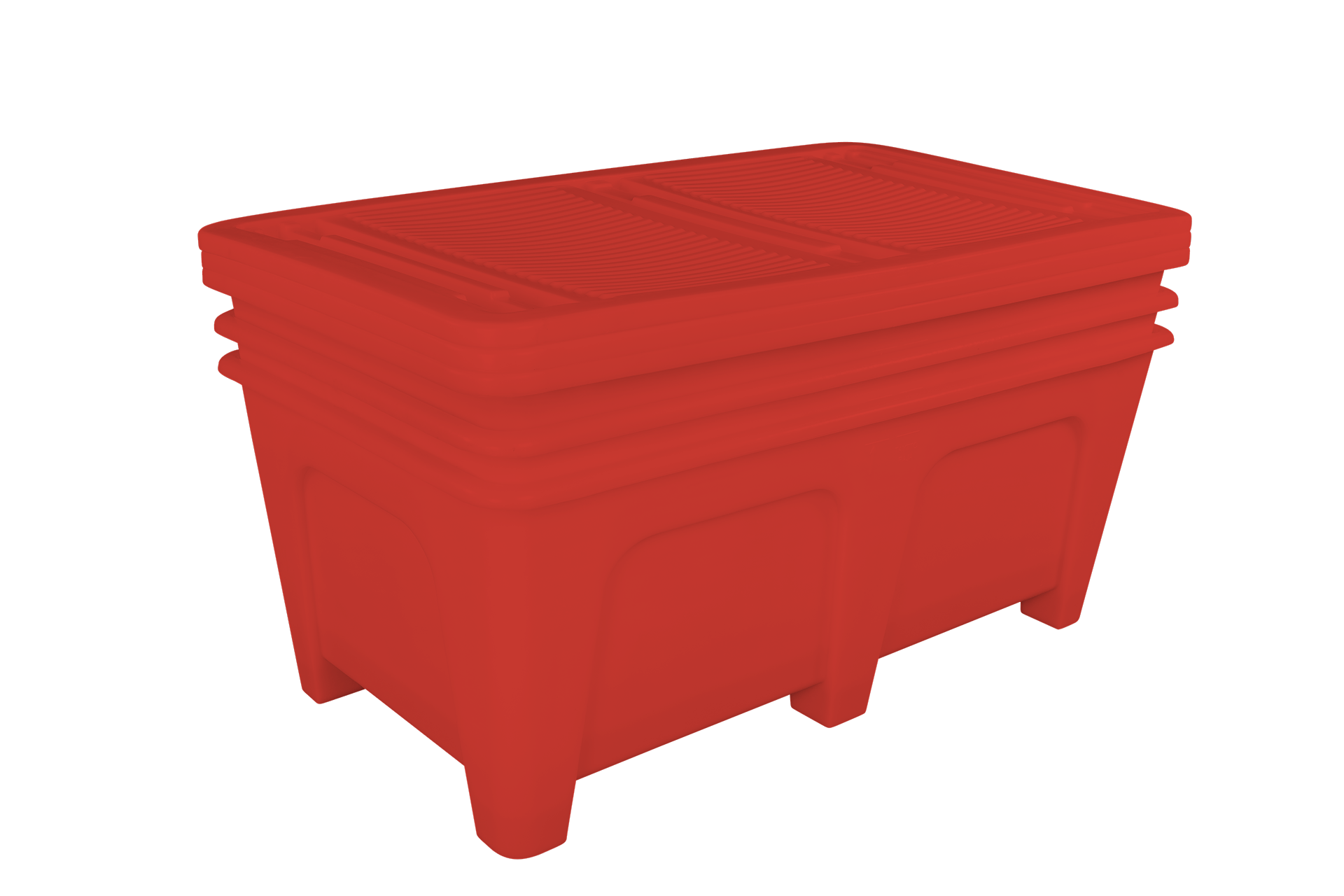

The LOGIBOX are made in one homogeneous piece of weather- and shockproof high quality polyethylene plastic material. It withstands abrasion, shocks and chemicals. The resin is food approved grade.

The standard color is natural white, but customer-specific colors are possible if needed.

Logibox lasts year after year, and at the end of its life cycle it can be fully recycled as durable plastics or it can be disposed of as energy waste.

By using Logibox, you reduce packaging waste and use transport and storage space more efficiently and economically.

LOGIBOX is spacious

The efficient packaging also has generous dimensions; length 1800mm, width 1000mm and height 700mm.

These dimensions creates a lot of possibilities for handling materials and components.

Weight of one empty Logibox is 38 kg.

LOGIBOX – for different needs

Logibox is specially designed for light products. In one package, you can pack max. 200 kg of products.

Areas of use include for example handling, logistics and storage of different types of recyclable and recycled materials, the plastic product manufacturing industry, component industry, storage of different materials, transfers from production points to assembly-units and outdoor storage of weatherproof components.

There are numerous areas of use and possibilities where single-use packaging can be omitted and products can be stored without storage shelves. Logiboxes circulate from the production point through intermediate storage to assembly lines.